Precision Solutions for Advanced Testing and Manufacturing – Engineering Reliability and Innovation in Every Component

At Mortimer Technologies, we specialise in the design and development of advanced measurement devices, sensors, electronics, and ultra-high vacuum equipment for precision applications. Our expertise includes creating bespoke solutions for leak detection, sealing, and vacuum processing, ensuring each product meets the highest industry standards. Engineered for critical testing and production environments, our equipment delivers superior reliability, efficiency, and stability. Whether your requirements involve vacuum creation, airtight sealing, or maintaining controlled conditions for specialised processes, Mortimer Technologies provides innovative, customised solutions that optimise both performance and cost-efficiency.

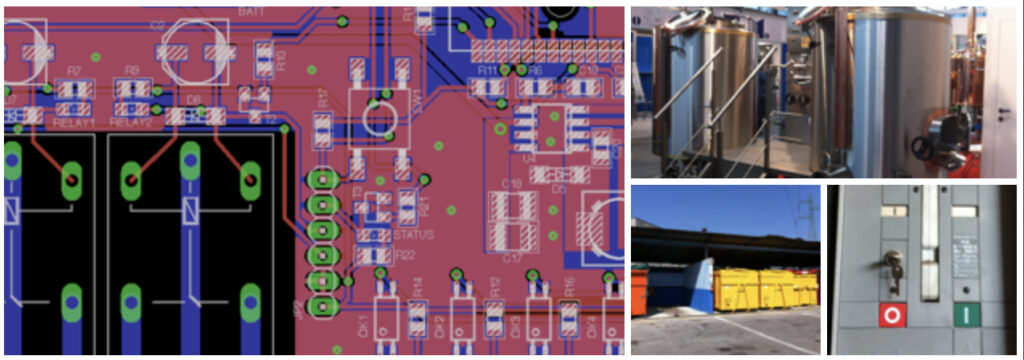

Industry 4.0 Process Automation

The Helium (He) Leak Line is a specialised machine designed to perform vacuum leak tests on custom components. It typically includes a worktable and an overhead hood, essential for creating a controlled vacuum environment. The system secures the component, applies a vacuum through dedicated inlets, and then injects a helium-nitrogen mixture to detect leaks with a high-precision helium detector. This machine incorporates integrated safety barriers, emergency stops, and a user-friendly HMI panel for operational control, along with Industry 4.0 capabilities for remote configuration and monitoring—ensuring secure and efficient testing in a connected, digital manufacturing environment.

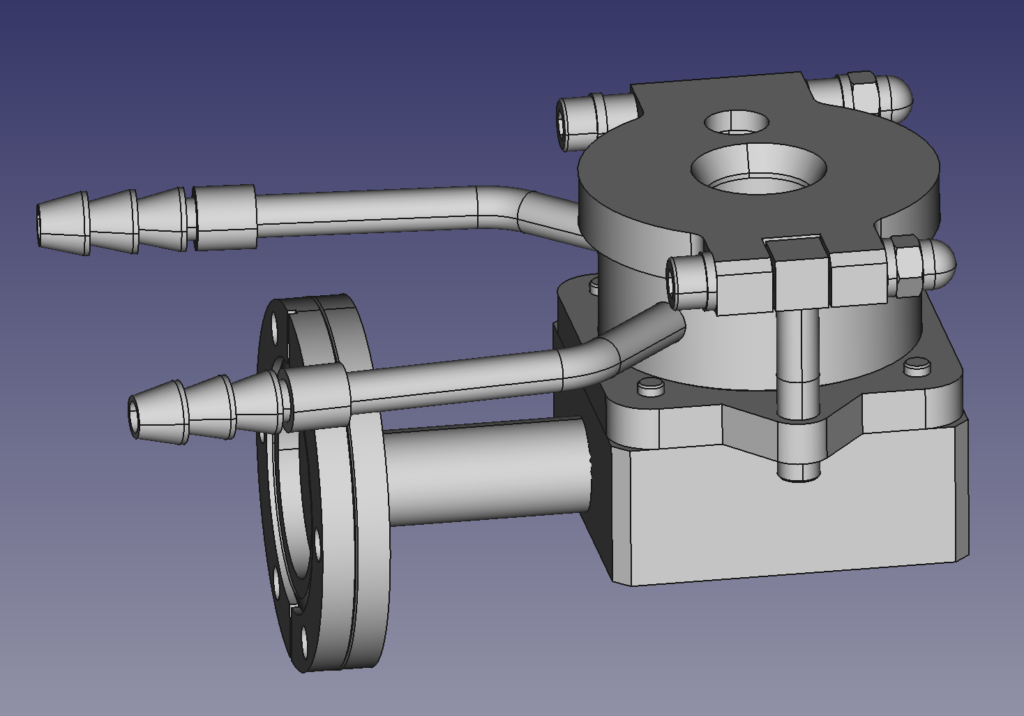

Mechanical Assembly Fixtures

We specialise in designing ultra-high vacuum-tight mechanical fittings for custom industrial applications, engineered to maintain vacuum integrity in highly automated environments with demanding conditions such as ovens and fluid systems. Our team supports clients in designing fittings for maximum efficiency and reliability, utilising advanced simulation and prototyping to ensure optimal performance.

Advanced Tooling

We supply hundreds of functional machine tools for integration into customers’ equipment, featuring poka-yoke functionality and tool recognition to automatically adjust machine parameters according to the selected tool. Integrated I/O service connections further eliminate operator error, enhancing reliability and ease of use. Our tooling and machinery are deployed across a wide range of applications and industries, including pressure and vacuum testing, brazing, conditioning and vacuum component production. They offer both passive and interactive (input/output) capabilities for power-up, operation, and functional verification through the use of sensors, mechanical actuation, and vision systems.